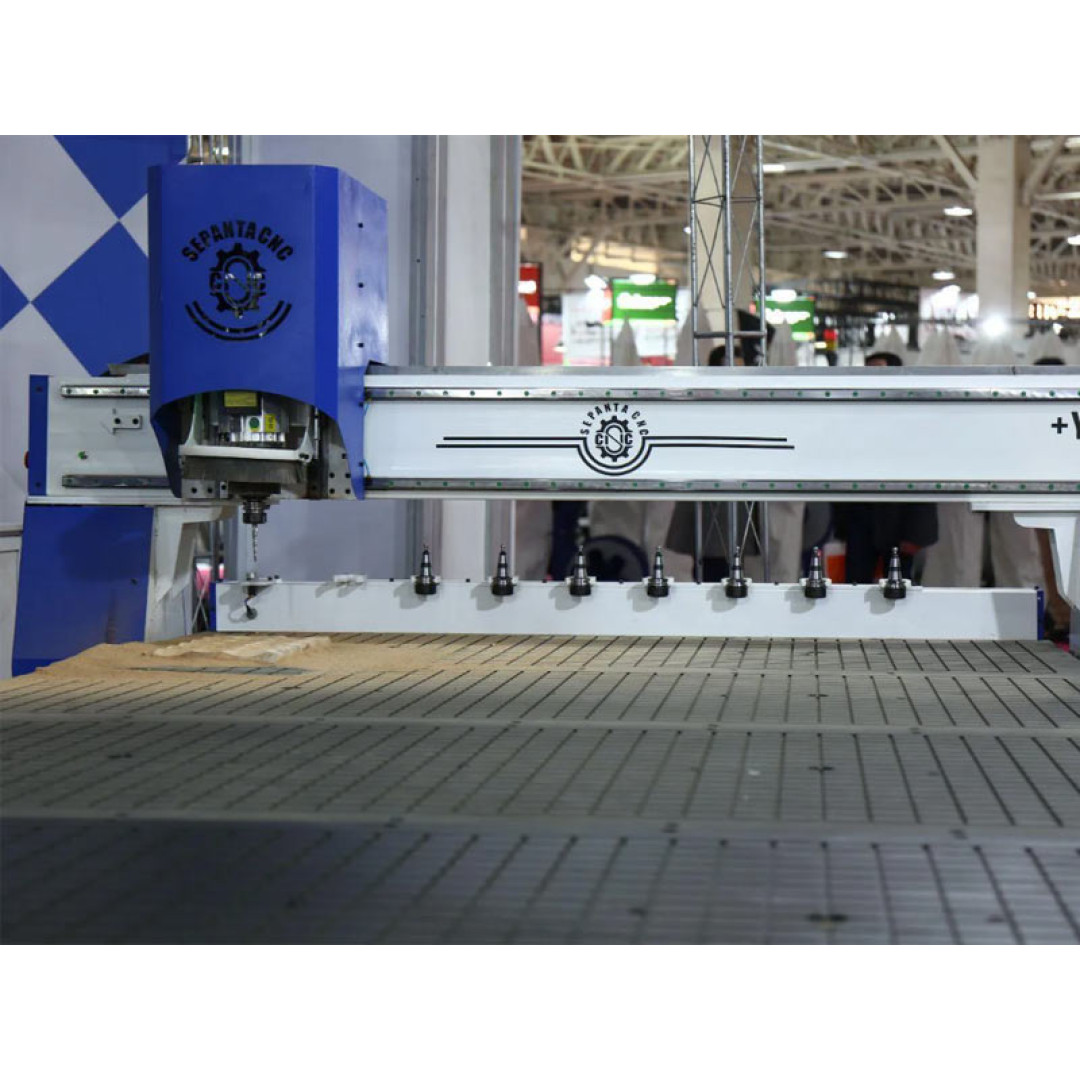

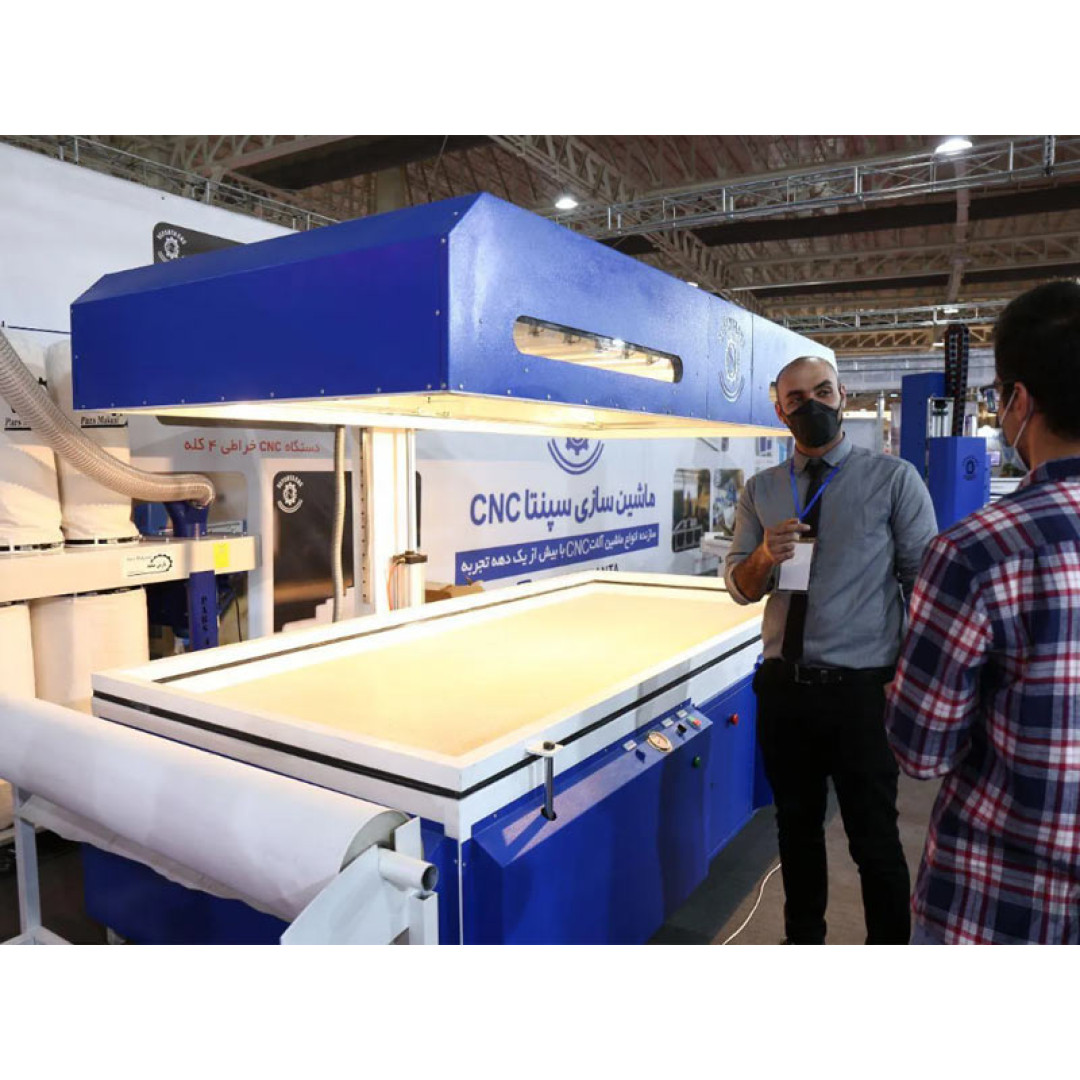

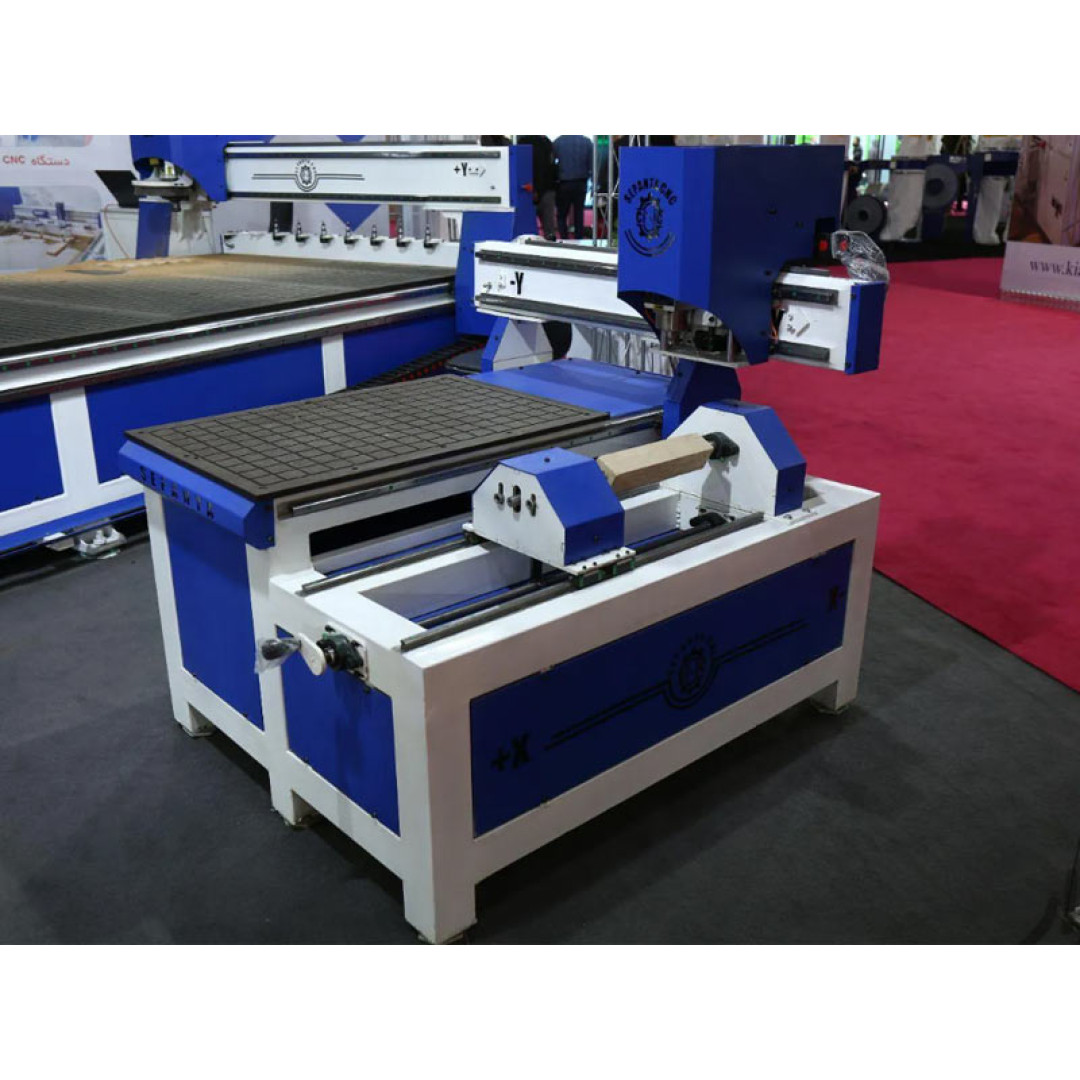

دستگاه پرس وکیوم

دستگاه پرس وکیوم ممبران-دستگاه روکش ممبران چوب، ام دی اف

دستگاه پرس وکیوم چوب که به دستگاه پرس وکیوم ممبران یا پرس ام دی اف هم مشهور است برای روکش کردن انواع ورق های خام یا فرزکاری شده چوب ، نئوپان و ام دی اف با روکش های pvc ، چرم و ..استفاده می گردد .

این دستگاه با نام پرس وکیوم ممبران نیز شناخته می شود و واژه ممبران نوعی روکش با همین نام است .

شرکت دانش بنیان سپنتا cnc تولید کننده انواع دستگاه پرس وکیوم با یک 1 سال ضمانت بی قید وشرط

|

جهت تماس آسان با ما ، بر روی شماره زیر کلیک نمایید تماس با بخش فروش:

مشاور آنلاین در واتس اپ: آدرس : کرج - ماهدشت ، شهرک صنعتی خوارزمی ، خیابان دهم ، کوچه میثاق ، بین پلاک 14 و 16 |

بیشترین کاربرد این دستگاه ها در صنایع کابینت سازی ، میز و صندلی و ..است . ورق های ام دی اف زمانی که توسط دستگاه cnc ، فرزکاری و طرح نگاری می گردند ، جلوه زیبایی ندارند و برای یکدست کردن سطح های صاف با قسمت های فرزکاری شده ، از روکش استفاده می نمایند.

این دستگاه با اعمال حرارت ، فشار و مکش ، روکش مورد نظر را بر روی سطح کار می چسباند . البته این نکته را باید در نظر داشته باشید که برخی از روکش ها دارای مواد چسبنده نیستند و باید قبل از روکش کشی سطح کار را به صورت یکنواخت به چسب آغشته نمود و سپس روکش را بر روی سطح گار گذاشت.

انواع دستگاه پرس وکیوم :

- پرس وکیوم آسانسوری

- پرس وکیوم ریلی

- پرس وکیوم صندوقی

معمولا قسمت درب دستگاه دارای سینی مجهز به المنت های الکتریکی هستند که سبب گرم شدن درب پرس می گردند و پمپ ایجاد خلا نیز در زیر دستگاه قرار دارد .

از دستگاه پرس وکیوم می توان جهت شکل دهی به چوب و روکش همزمان آن استفاده نمود که لازمه این کار استفاده از سینی قالبی در کف و درب میز است .

فیلم کارکرد دستگاه پرس وکیوم آسانسوری سپنتا سی.ان.سی

دستگاه پرس وکیوم چوب

مشخصات دستگاه وکیوم سپنتا ابعاد میز کار: 123*283 سانتی متر ابعاد دستگاه: 140*300 سانتی متر ارتفاع دستگاه : بسته 160 باز 210 سیستم عملکرد م..

335,000,000 تومان

دستگاه پرس وکیوم برای روکشکاری چوب با استفاده از فشار منفی (وکیوم) بهمنظور قرار دادن روکشهای PVC، لمینت، وینیل و غیره روی سطح چوب استفاده میشود.

برای استفاده از دستگاه پرس وکیوم برای روکشکاری چوب، ابتدا روکش بر روی سطح چوب قرار میگیرد و سپس دستگاه با استفاده از وکیوم، روکش را بهدقت به چوب میچسباند.

دستگاه پرس وکیوم برای روکشکاری چوب دقت بالا، چسبندگی یکنواخت و سرعت بالای تولید را فراهم میکند. همچنین باعث صرفهجویی در زمان و کاهش ضایعات میشود.

دستگاه پرس وکیوم میتواند انواع روکشها مانند PVC، لمینت، وینیل، کاغذ و چرم را به چوب بچسباند.

بله، دستگاه پرس وکیوم برای روکشکاری چوب در مقیاس بزرگ مناسب است و میتواند حجم بالایی از قطعات چوبی را با کیفیت و سرعت بالا روکشکاری کند.

اگر دستگاه بهدرستی تنظیم شود، هیچگونه آسیبی به چوب وارد نمیکند. فشار وکیوم بهطور یکنواخت و متناسب با نوع چوب اعمال میشود.

برای بهبود کیفیت روکشکاری، باید از روکشهای با کیفیت بالا، تنظیمات صحیح فشار وکیوم، و دمای مناسب استفاده کرد. همچنین سطح چوب باید صاف و تمیز باشد.

هزینه دستگاه پرس وکیوم بسته به ابعاد و ویژگیهای دستگاه متغیر است، اما در مقایسه با سایر روشهای روکشکاری، هزینههای عملیاتی آن بهصرفه است.

تنظیم دستگاه پرس وکیوم برای روکشکاری چوب شامل تنظیم فشار وکیوم، دما و زمان اعمال وکیوم است. این تنظیمات باید با توجه به نوع چوب و روکش انتخابی صورت گیرد.